The future of housing construction is unfolding, with profound implications for eco-conscious consumers, housing developers, and technology enthusiasts. Today, we’re excited to bring you an in-depth look at Plant Prefab’s groundbreaking automated factory dedicated to building sustainable multifamily and single-family housing.

Plant Prefab’s Innovative Approach

Plant Prefab is no ordinary construction company. It proudly wears the badge of a Certified B Corporation™, reflecting a steadfast commitment to sustainability from design to operations. This commitment has culminated in the creation of a new automated factory—a true industry first in sustainability-focused multifamily and single-family housing construction.

The facility represents a significant leap forward in addressing critical housing shortages in supply-constrained markets while also delivering on the promise of environmental sustainability. The Tejon Ranch Commerce Center chosen for this facility serves strategic and sustainability-oriented goals, keeping with the mission to create more accessible architectural and sustainable housing.

Features of the Automated Factory

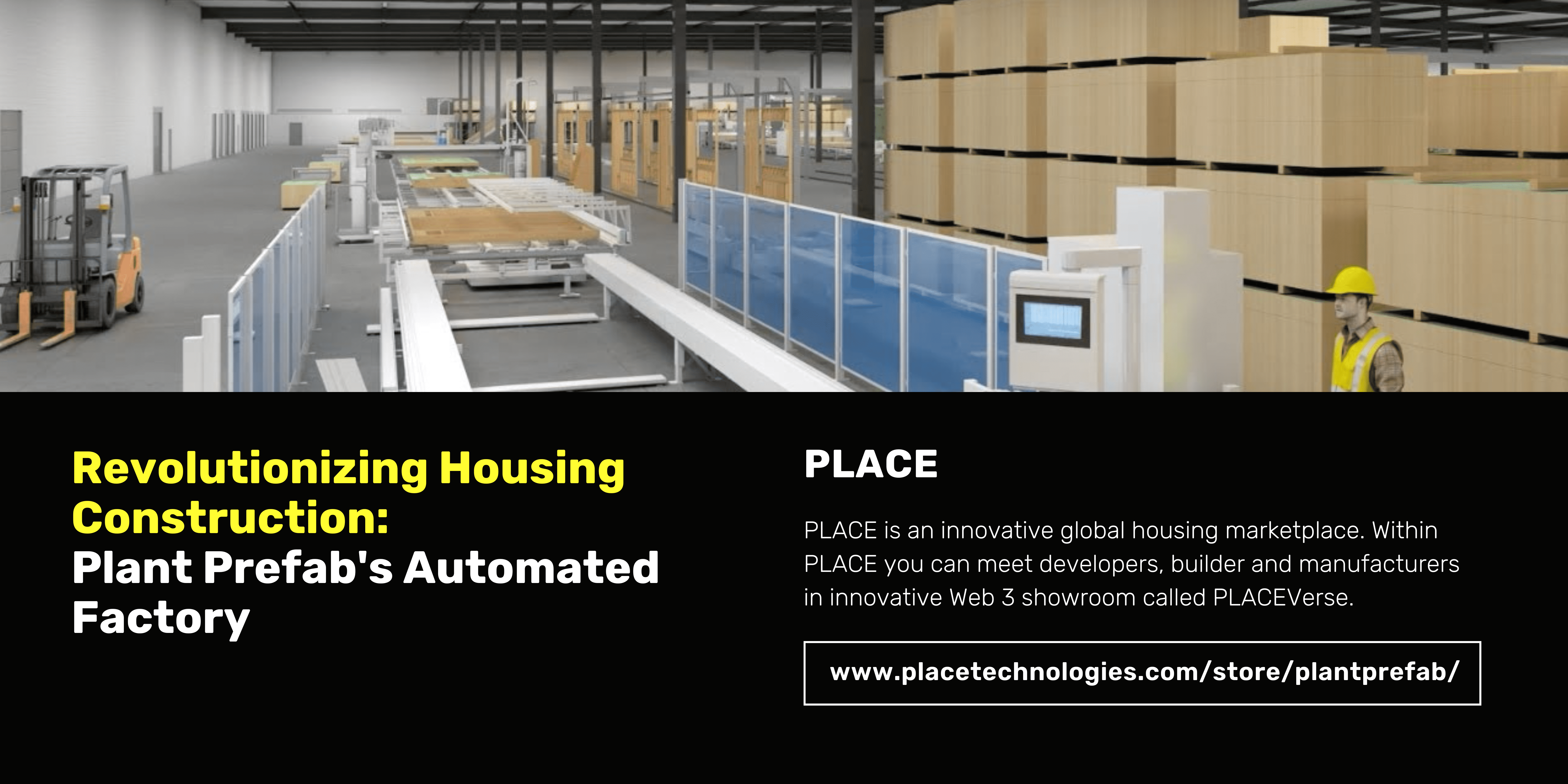

Located 25 miles south of Bakersfield, California, this 270,000-square-foot facility, spanning 17 acres, promises a new era of housing construction:

- Advanced Production Methods: This factory will use sophisticated machinery directed by digital modeling data for high-efficiency production of custom-prefabricated components.

- Exceptional Velocity and Quality: By automating production, Plant Prefab aims to accelerate build times while ensuring top-quality construction that is unmatched in the custom housing segment.

Benefits and Impact

Housing developers and eco-minded consumers alike can anticipate numerous benefits from this development:

- Efficiency in Time and Cost: With the Plant Building System™️, housing can be constructed 20 to 50 percent faster with significant cost savings in labor-intense markets.

- Energy-Efficient Living Spaces: In 2020 alone, homes built by Plant Prefab exceeded California’s energy efficiency standards, a testament to the potential for a lower carbon footprint.

- Job Creation and Regional Impact: Up to 440 individuals will gain employment, highlighting the positive social impact tied to technology and sustainability efforts.

Future Prospects

The construction of this automated factory marks just the beginning. Plant Prefab plans to replicate this hub-and-spoke model across other regional markets, expanding its reach and continuing to address urgent housing needs.

Bringing Together Mission and Technology

Our story is not just about construction—it’s a tale of integrating ethos and technology to better our world. Like Plant Prefab, PLACE shares a vision of reducing greenhouse gas emissions and waste within their operations, creating a model for sustainable business practices that has applications far beyond housing. Acting as an industry connector to accelerate adoption of services like those pioneered by Plant Prefab.

PLACE is an innovative global housing marketplace. Within PLACE you can meet developers, builder and manufacturers in innovative Web 3 showroom called PLACEVerse. We publish articles daily, sign up for our newsletter weekly digest here, or join our community here.