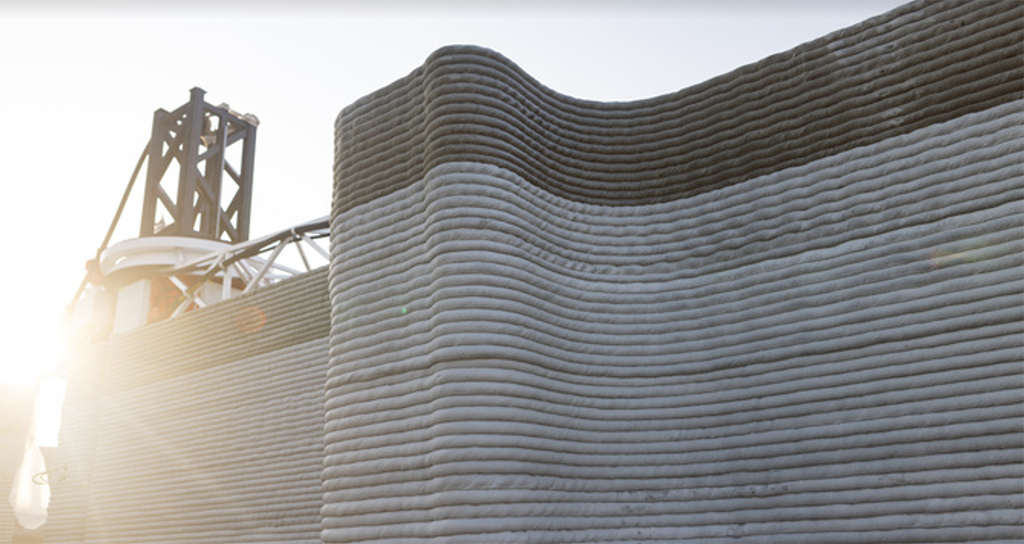

The construction industry has been around as long as human civilization, but it has changed vastly over centuries. The traditional methods of constructing houses have seen different variations through the years, but none has caused a disruption as significant as 3D printed houses. The technology is transforming the construction industry, leaving a minimal environmental footprint while yielding fast and affordable construction. This blog explores the trend of 3D printed houses in North America and the rest of the world, focusing on BioHome 3D, Icon Build, and Mighty Buildings.

BioHome3D, Scientists at the University of Maine have created the “Biohome3D,” a house that was 3D-printed from 100% natural materials. At a cozy 600 square feet, it’s far from a mansion, but it towers above the world’s most colossal residences in its own way — namely that it’s the first-ever 3D-printed home to be made fully of environmentally-friendly components.

Icon Build, a construction company based in Austin, Texas, has also adopted the use of 3D printing technology in construction. The company uses 3D printers to cut the cost and time it takes to construct homes and buildings. The technology has allowed the company to significantly lower their environmental impact while still staying competitive in the industry. Icon Build uses a proprietary mix of natural materials and recycled waste to build their structures, which addresses two critical concerns – sustainable construction and waste management.

Another company to watch in the adoption of 3D printed houses is Mighty Buildings from California. Mighty Buildings uses 3D printing technology to create houses, mainly focusing on accessory dwelling units (ADUs). The technology of the company allows it to build not only ADUs but offices, living spaces, and other small buildings faster and at a lower cost. Mighty Buildings’ solution has disrupted traditional construction methods as they can produce houses up to 80% faster at a fraction of the construction cost.

According to industry experts, the trend of 3D printed houses is expected to grow in adoption globally. With the no. of 3D printing design software Young graduates have access to, skills, knowledge, and expertise in 3D printers will be readily available, making it easier to train more professionals in the industry. The technology has started to make an impact in Europe, where the Netherlands has produced a complete 3D printed home with every part of it 3D printed, including furniture. The 3D printed house was completed in less than six months, which highlights the technology’s speed and efficiency.

The 3D printing industry has seen massive growth, and thanks to companies like BioHome3D, Icon Build, and Mighty Buildings, the adoption of 3D printing in housing construction is on an upward trajectory. Sustainable, affordable, customizable, and fast 3D printed houses are disrupting traditional construction methods, leaving a minimal environmental impact. The rise of 3D printed houses will undoubtedly decrease the cost of housing and make homeownership a real possibility for many people globally. With the ever-growing need for sustainable, energy-efficient homes, many more companies will adopt 3D printing technology. The technology’s future in the construction industry looks bright.